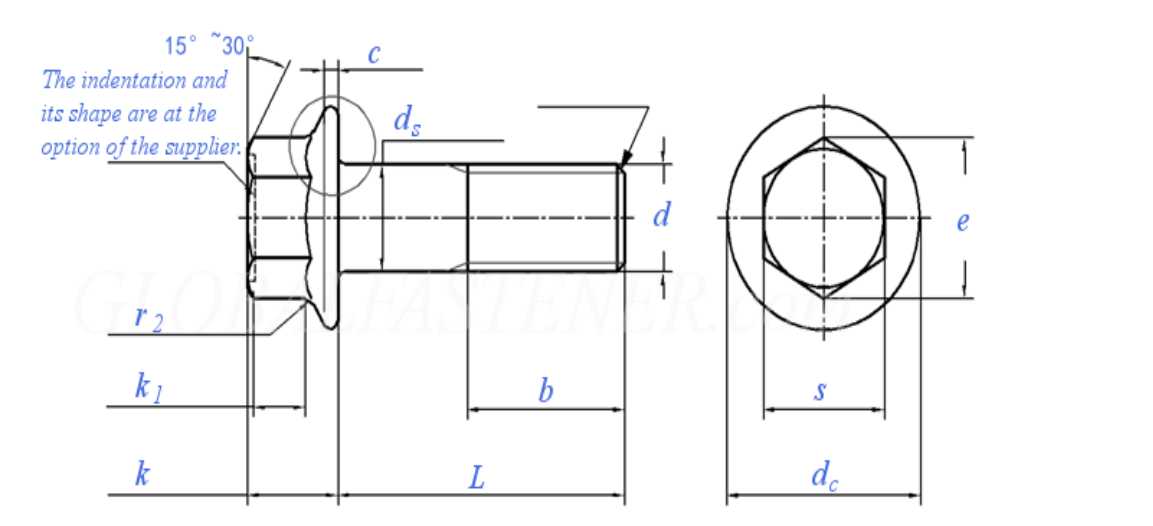

| Screw Thread d | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 | ||||

| P | Pitch | Coarse thread | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | ||

| Fine thread-1 | / | / | 1 | 1.25 | 1.5 | 1.5 | 1.5 | 1.5 | ||||

| Fine thread-2 | / | / | / | 1 | 1.25 | / | / | / | ||||

| b | L≤125 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 46 | |||

| 125<L≤200 | / | / | 28 | 32 | 36 | 40 | 44 | 52 | ||||

| L>200 | / | / | / | / | / | / | 57 | 65 | ||||

| c | min | 1 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | |||

| da | Form A | max | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 22.4 | ||

| Form B | max | 6.2 | 7.4 | 10 | 12.6 | 15.2 | 17.7 | 20.7 | 25.7 | |||

| dc | max | 11.8 | 14.2 | 18 | 22.3 | 26.6 | 30.5 | 35 | 43 | |||

| ds | max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |||

| min | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 | ||||

| du | max | 5.5 | 6.6 | 9 | 11 | 13.5 | 15.5 | 17.5 | 22 | |||

| dw | min | 9.8 | 12.2 | 15.8 | 19.6 | 23.8 | 27.6 | 31.9 | 39.9 | |||

| e | min | 8.71 | 10.95 | 14.26 | 16.5 | 17.62 | 19.86 | 23.15 | 29.87 | |||

| f | max | 1.4 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | |||

| k | max | 5.4 | 6.6 | 8.1 | 9.2 | 11.5 | 12.8 | 14.4 | 17.1 | |||

| k1 | min | 2 | 2.5 | 3.2 | 3.6 | 4.6 | 5.1 | 5.8 | 6.8 | |||

| r1 | min | 0.25 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | 0.8 | |||

| r2 | max | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.9 | 1 | 1.2 | |||

| r3 | min | 0.1 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.4 | |||

| r4 | ≈ | 3 | 3.4 | 4.3 | 4.3 | 6.4 | 6.4 | 6.4 | 8.5 | |||

| s | max=nominal size | 8 | 10 | 13 | 15 | 16 | 18 | 21 | 27 | |||

| min | 7.78 | 9.78 | 12.73 | 14.73 | 15.73 | 17.73 | 20.67 | 26.67 | ||||

| t | max | 0.15 | 0.2 | 0.25 | 0.3 | 0.35 | 0.45 | 0.5 | 0.65 | |||

| min | 0.05 | 0.05 | 0.1 | 0.15 | 0.15 | 0.2 | 0.25 | 0.3 | ||||

application area

The type requirements of hexagon flange bolts are different according to different places of use. Generally speaking, hexagon flange bolts are widely used in industrial and civil construction, cranes, excavators and other heavy machinery.

It is said that every man has a dream to open an excavator. Let's unlock the application and mystery of the excavator.

excavating machinery

Thin rod flange bolts are conducive to connection under variable force. The stress mode of excavator bolt connection can be divided into ordinary and reamed holes. Flange bolts for reaming holes shall be matched with the size of the hole when subjected to transverse force. In order to meet the needs of locking after installation of the excavator, there are holes in the rod, which can prevent the bolt from loosening when subjected to vibration. When installing the matching bolts on the excavator, the bolt head shall be at the upper side of the connection, and the nuts and bolt heads shall be simultaneously back pressed from the bolt connection center to the edge (in four directions) to complete the fastening of the bolts.

Anti corrosion protection and sealing of bolted connection In order to prevent plastic deformation under external tension, a layer of primer (such as epoxy resin, zinc powder, etc.) can be painted on the contact surface of bolted connection, or the bolt has its own coating.

With the change of market demand, various new varieties of hexagon flange bolts have been derived. Cross recessed raised hexagon head bolt, hexagon flange wood bolt, hexagon flange triangular self-locking bolt, hexagon flange self tapping self drilling bolt, hexagon flange self tapping self drilling bolt (coating+EPDM composite gasket), etc.